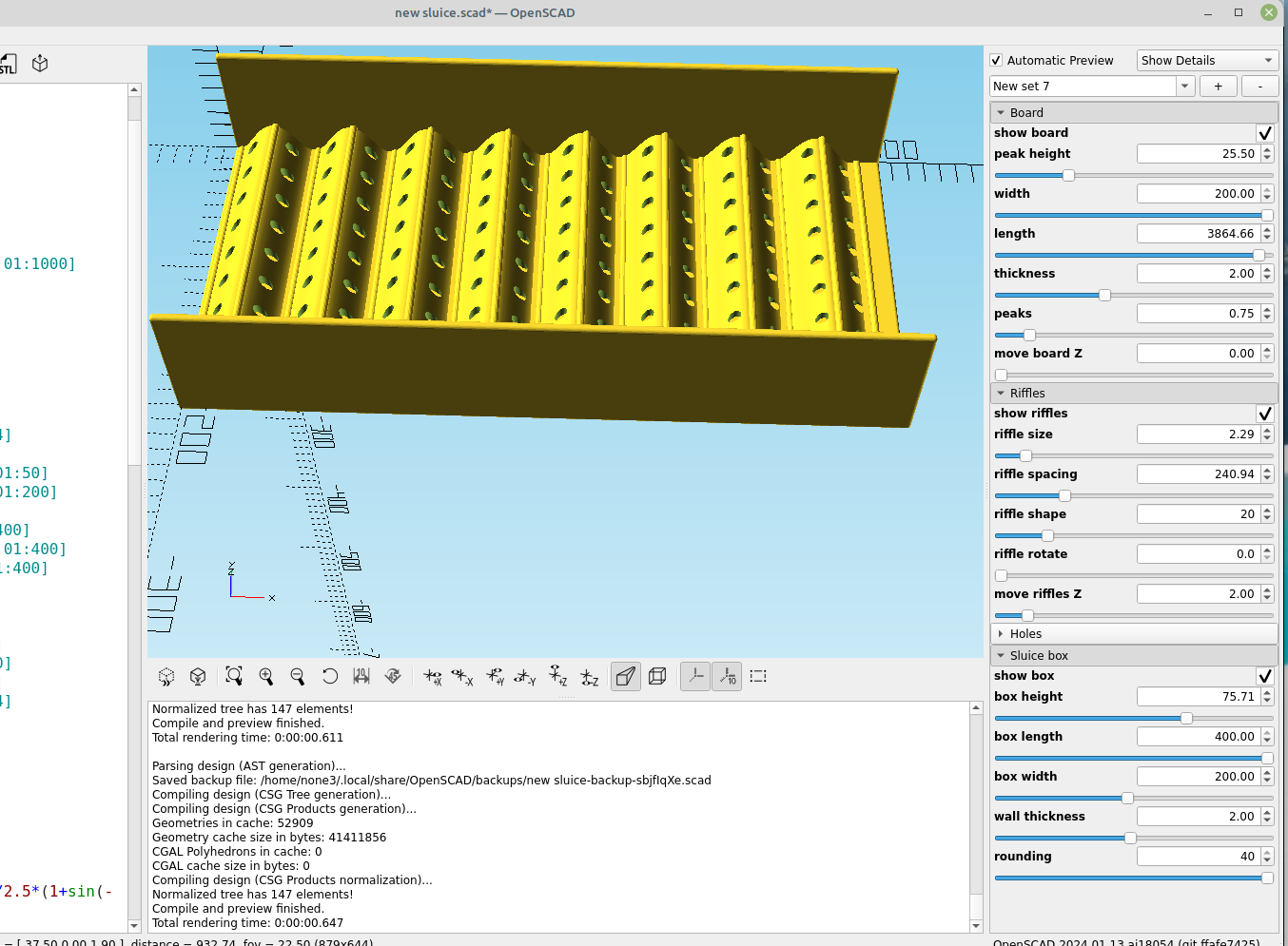

Since I needed to make a box for the corrugated riffle customizer I had made in post #67 I used the code I had already made for the parts box from post #65 and modified it for a sluice.

Here is the code:

/*[Board]*/

show_board= true;

peak_height = 25.5;//[0:.01:100]

width = 200; // [0:.01:400]

length = 1919; //[0:.01:4000]

thickness = 2; // [.1:.01:5]

peaks = .75; // [0:.01:7]

move_board_Z=0;//[0:.01:20]

/*[Riffles]*/

show_riffles= true;

riffle_size=2.29;//[0:.01:25]

riffle_spacing = 240.94;//[1:.01:1000]

riffle_shape=20; //[3:1:100]

riffle_rotate=0;//[0:.1:360]

move_riffles_Z=2;//[0:.01:20]

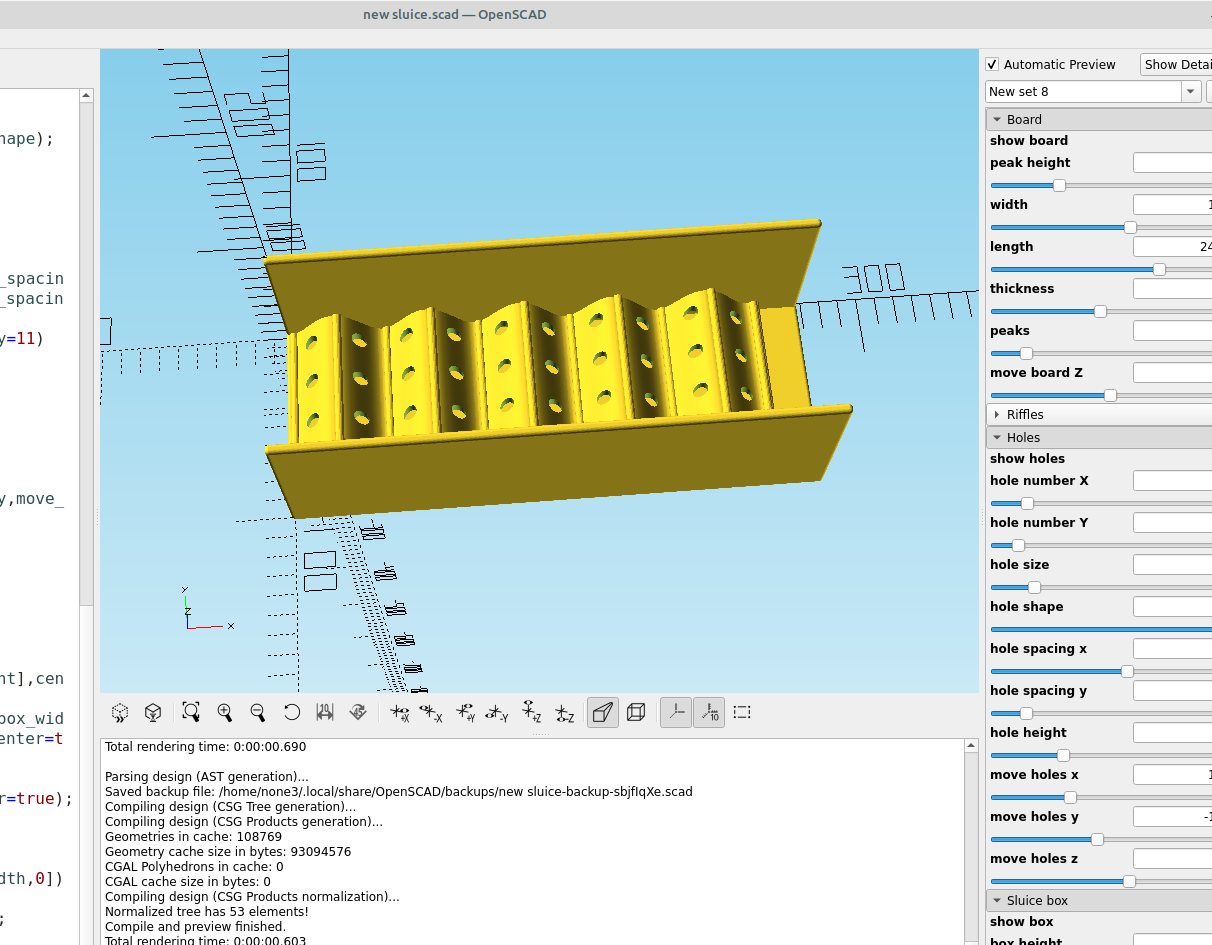

/*[Holes]*/

show_holes= true;

hole_number_X=8; //[1:1:100]

hole_number_Y=9; //[1:1:100]

hole_size = 3.5; //[0:.01:25.4]

hole_shape = 50; //[3:1:50]

hole_spacing_x = 24.46;//[0:.01:50]

hole_spacing_y = 21.62;//[0:.01:200]

hole_height=50;//[.1:.01:200]

move_holes_x = 110; //[0:.01:400]

move_holes_y = -100; //[-400:.01:400]

move_holes_z = -4; //[-400:.01:400]

/*[Sluice box]*/

show_box= true;

box_height = 50;//[20:.01:100]

box_length = 200;//[20:.01:400]

box_width = 200;//[20:.01:400]

wall_thickness = 2;//[.1:.01:4]

rounding = 40; //[4:1:40]

module board(){

if (show_board)

translate([0,0,move_board_Z])

rotate([90,0,0])

linear_extrude(width)

for (i=[0:length]){

hull(){

translate([i*.1,peak_height/2.5*(1+sin(-90+i*peaks)),0])

circle(thickness,$fn=20);

translate([(i+1)*.1,peak_height/2.5*(1+sin(-90+(i+1)*peaks)),0])

circle(thickness,$fn=20);

}}}

module riffles(){

if (show_riffles)

translate([riffle_size,0,move_board_Z])

rotate([90,0,0])

linear_extrude(width)

translate([0,move_riffles_Z,0])

for (i=[0:riffle_spacing:length]){

translate([i*.1,peak_height/2.5*(1+sin(-90+i*peaks)),0])

rotate([0,0,riffle_rotate])

circle(riffle_size,$fn=riffle_shape);

}}

module holes(){

if (show_holes)

for(x=[0:hole_number_X-1])

for(y=[0:hole_number_Y-1])

translate([(x-hole_number_X/2)*hole_spacing_x,(y-hole_number_Y/2+.5)*hole_spacing_y,-5])

linear_extrude(hole_height,convexity=11)

circle(hole_size,$fn=hole_shape);

}

riffles();

difference(){

board();

translate([move_holes_x,move_holes_y,move_holes_z])

holes();

}

module box(){

if (show_box){

translate([0,0,box_height/2])

difference(){

cube([box_length,box_width,box_height],center=true);

cube([box_length-wall_thickness+12,box_width-wall_thickness,box_height],center=true);

}

cube([box_length,box_width,1],center=true);

}}

if (show_box){

minkowski(){

translate([.5*box_length,-.5*box_width,0])

box();

sphere(wall_thickness,$fn=rounding);

}}

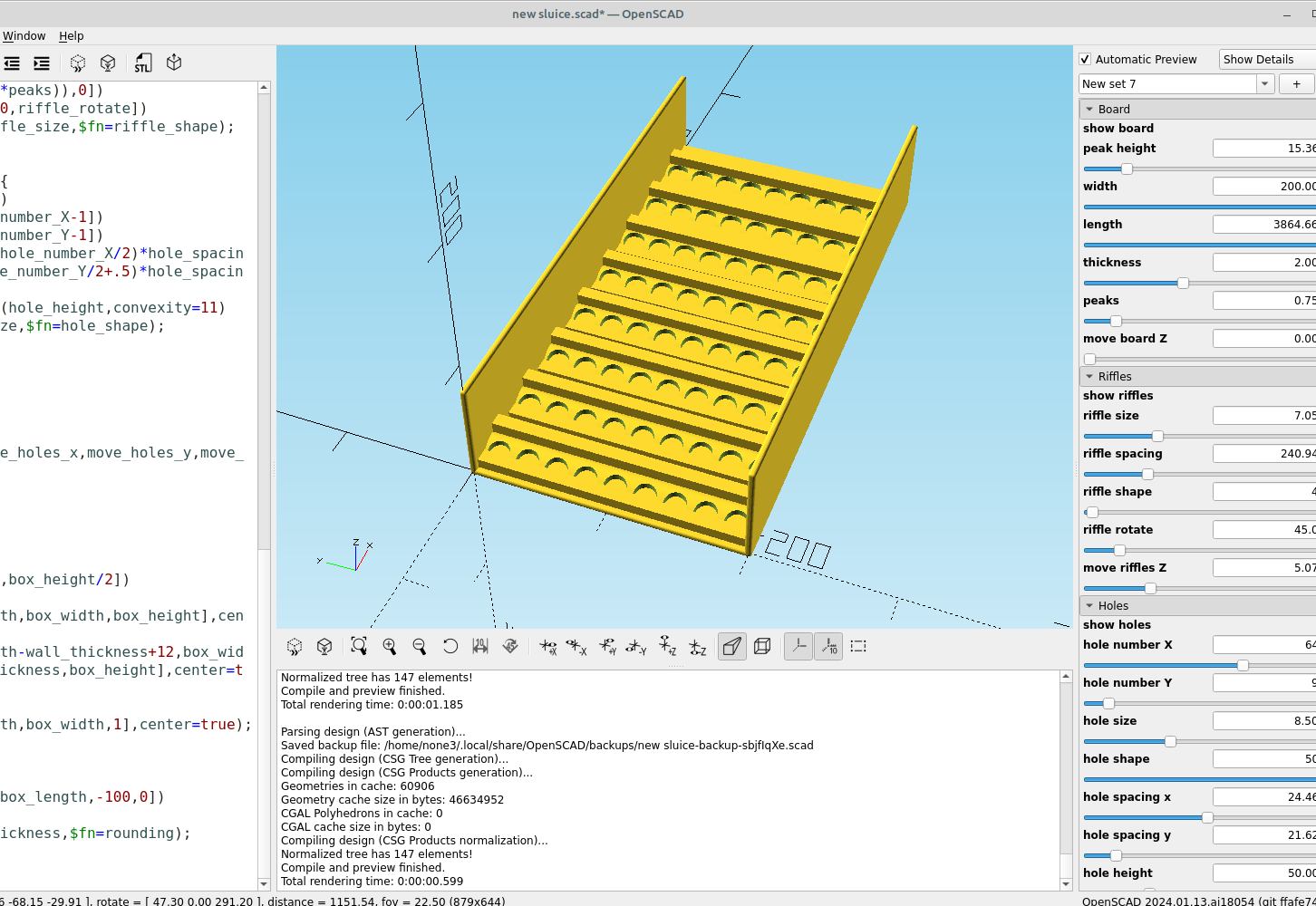

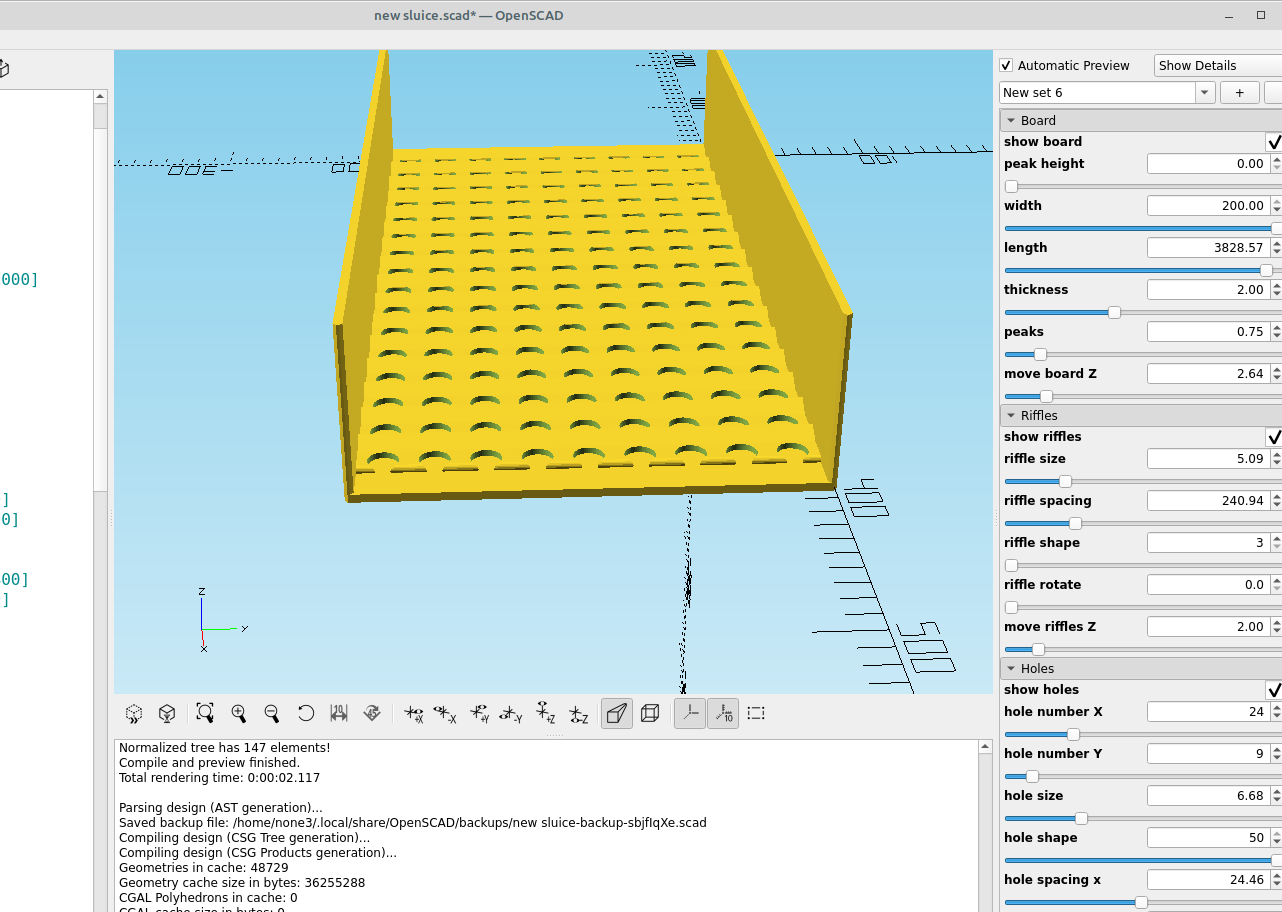

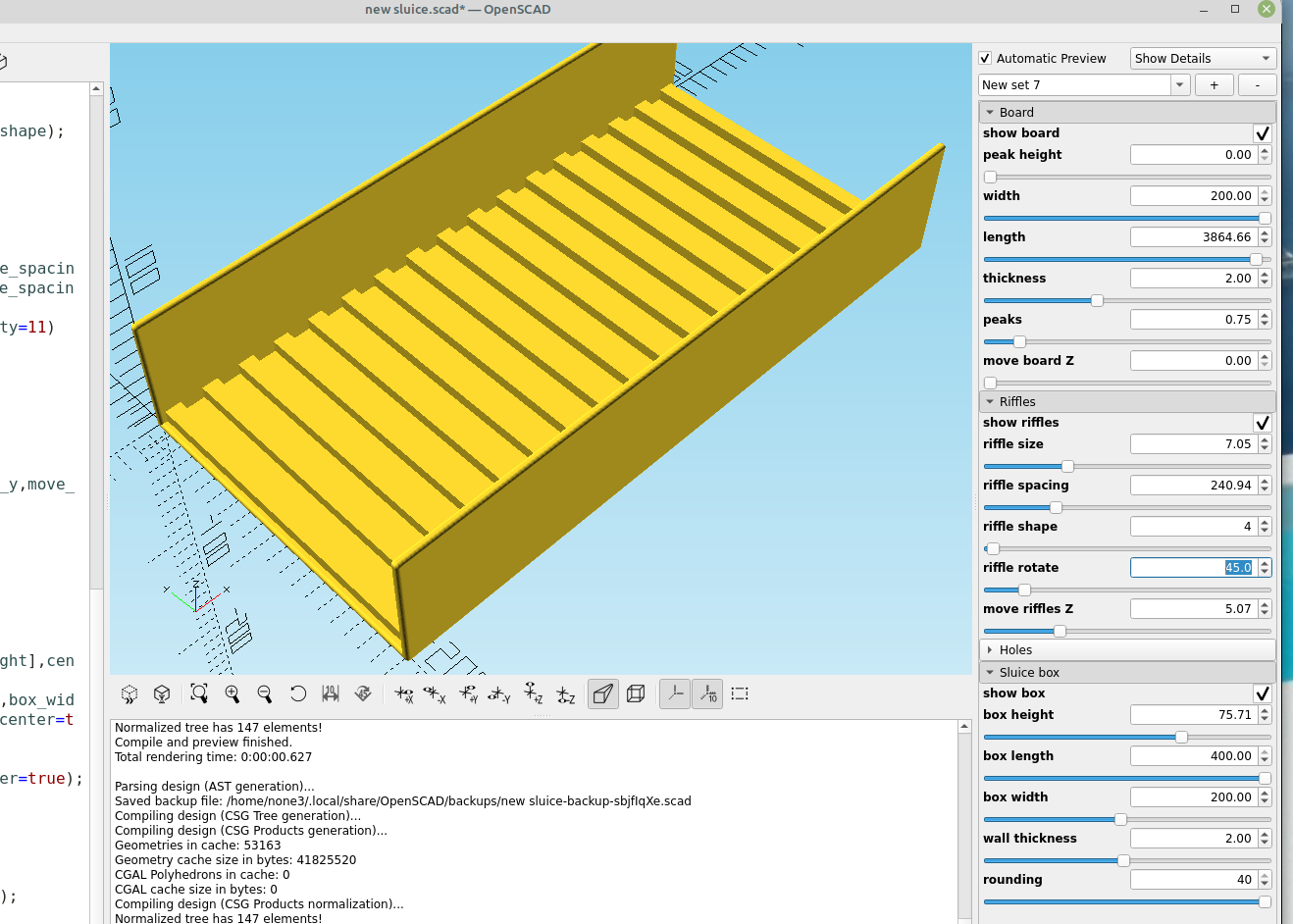

Now I can turn off or on the different sections and print them out separately or all at one time.

Now I can add carpet or miners moss under the riffles and make it small for backpacking.

As time allows I will be making improvements and adding additional features like snap together sections and a header box.