Recently I saw a really cool video where they were making patterns on knives with 3d printed canisters, and since it's really easy to make these with Inkscape and OpenSCAD I figured I would do a write up on it.

Here is a link to one of the videos explaining the process:

And a link to an excellent description of the process:

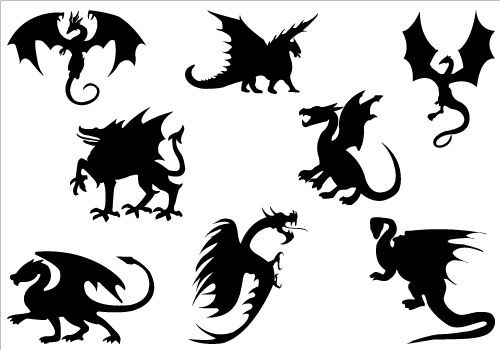

First thing you need is a pattern, I chose a free dragon design from here:

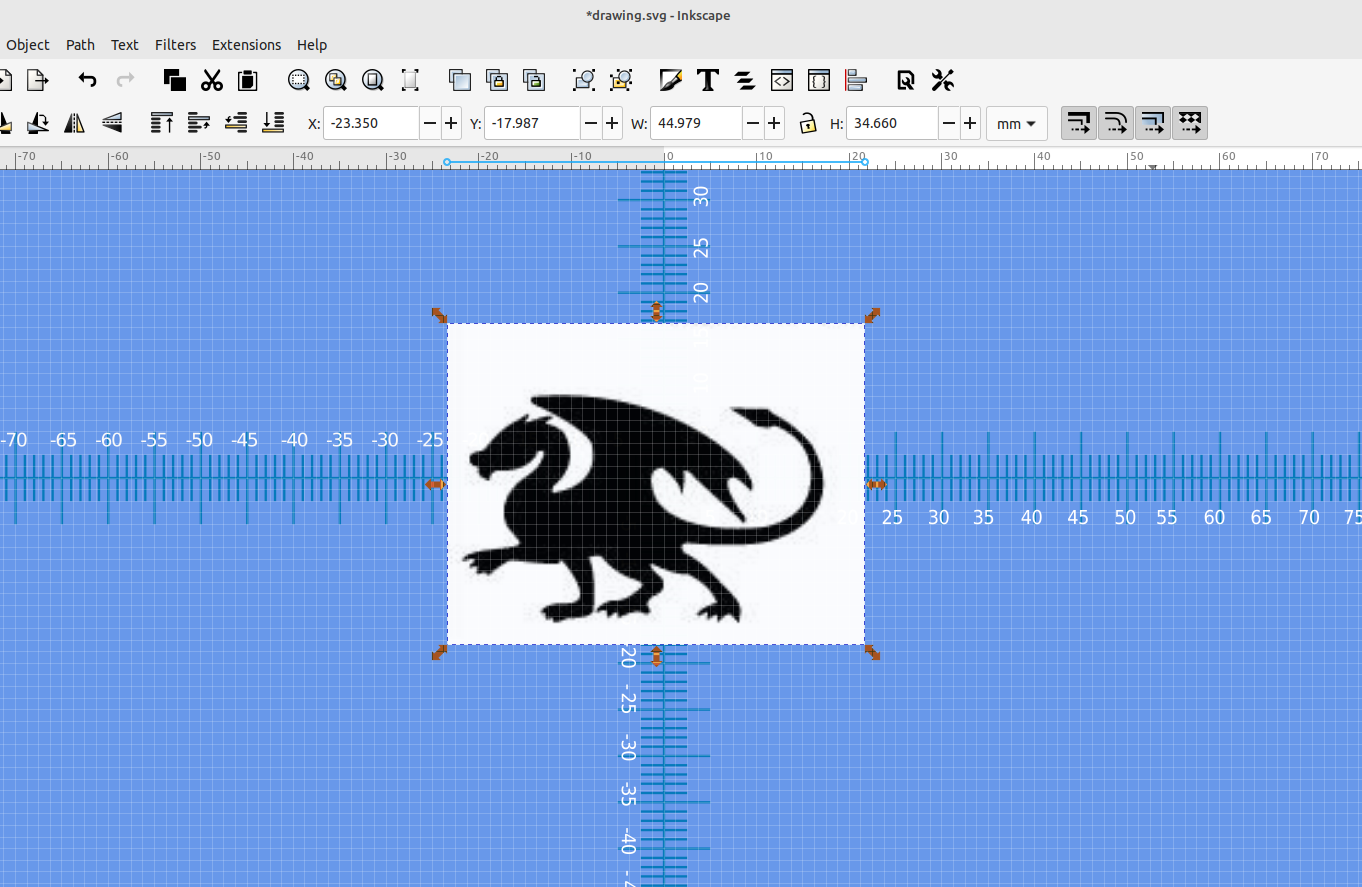

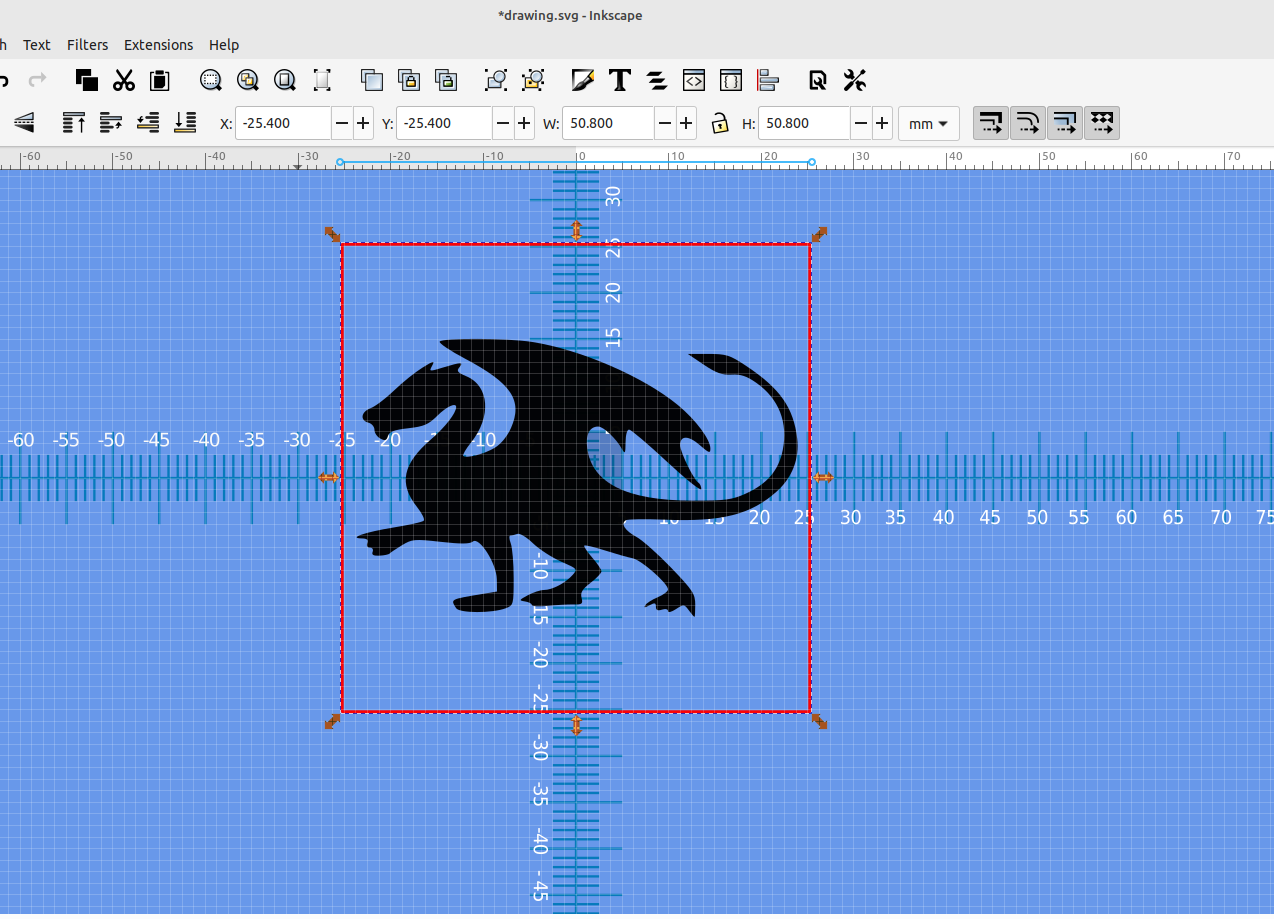

Then I imported the image into Inkscape and traced it:

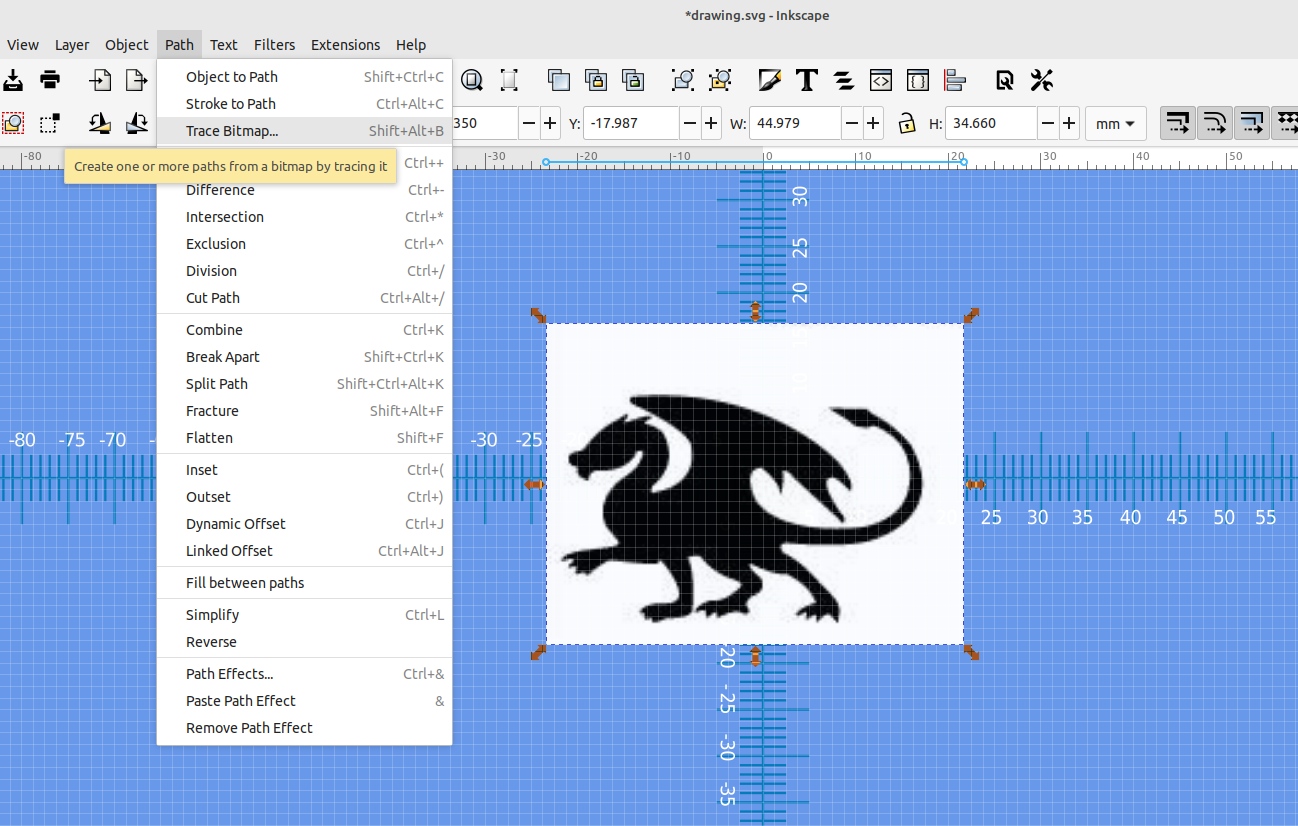

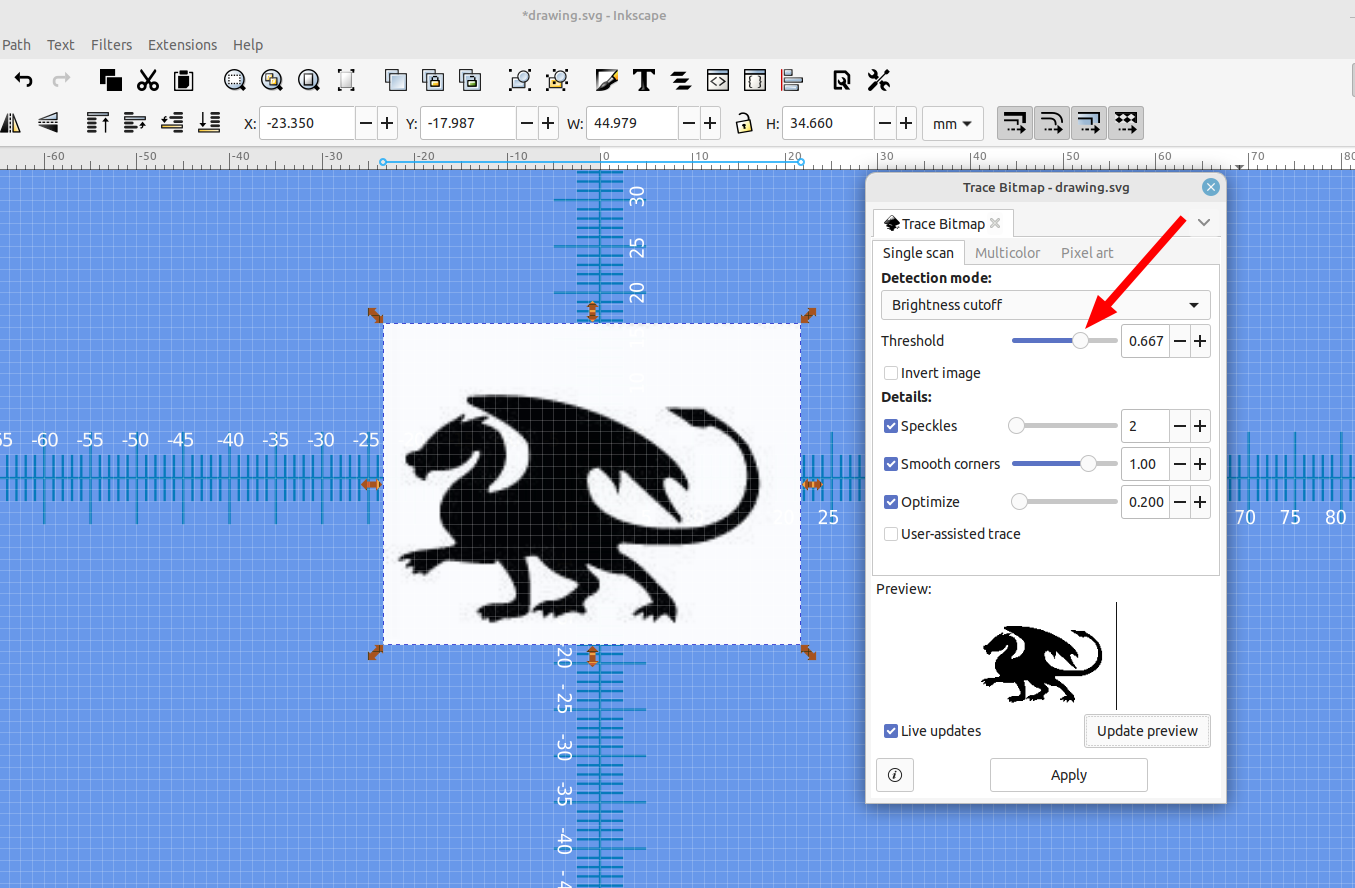

To trace the image select it and goto Path>Trace Bitmap

In the Trace Bitmap dialog adjust the threshold until it has the detail you want and click apply, for black and white images the default setting is usually fine.

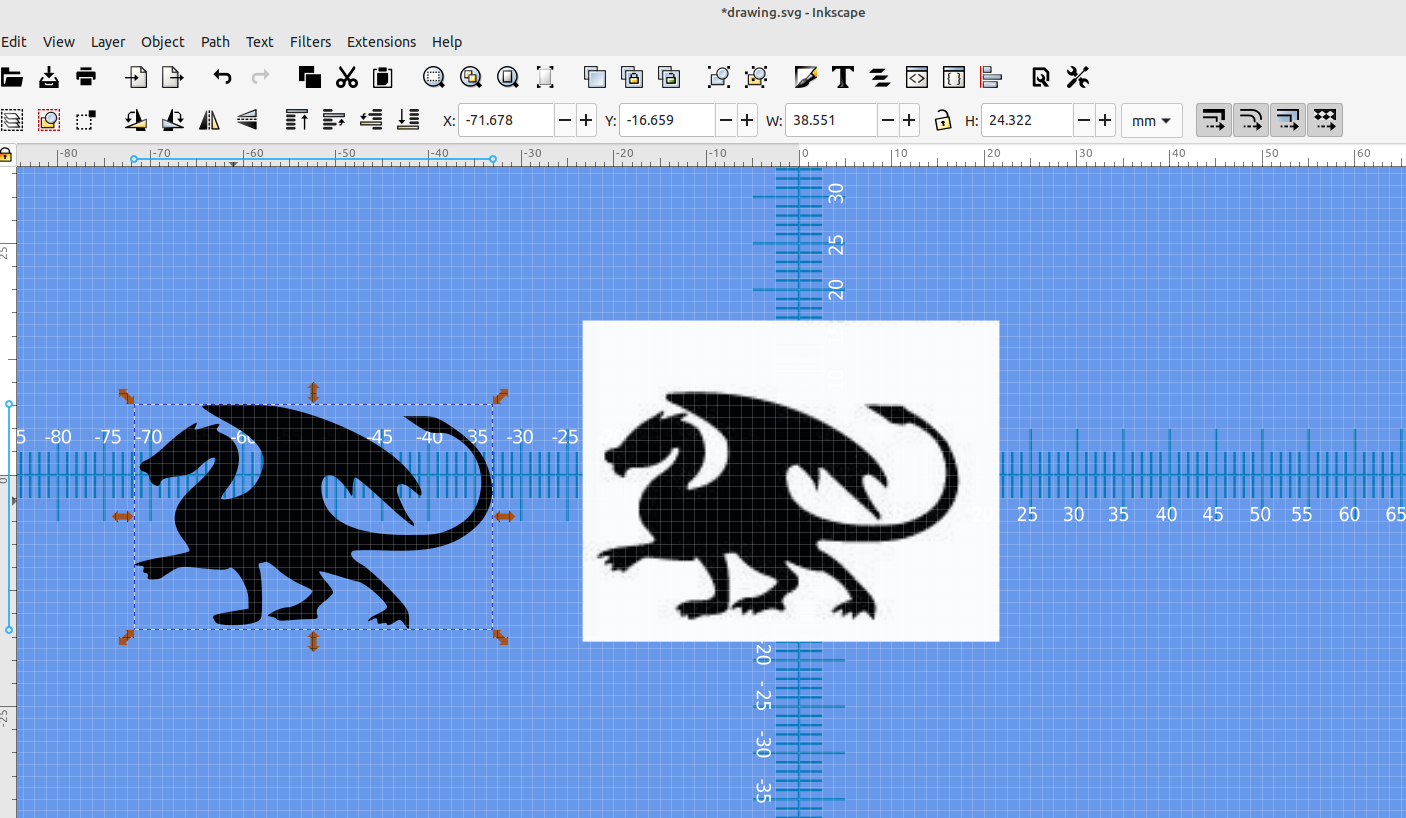

Once you have your traced image drag it to the side and delete the original image with the white box around it:

I added a square that is the size of the outside canister so I could adjust the traced image to the size I wanted it to be, then I deleted the square.

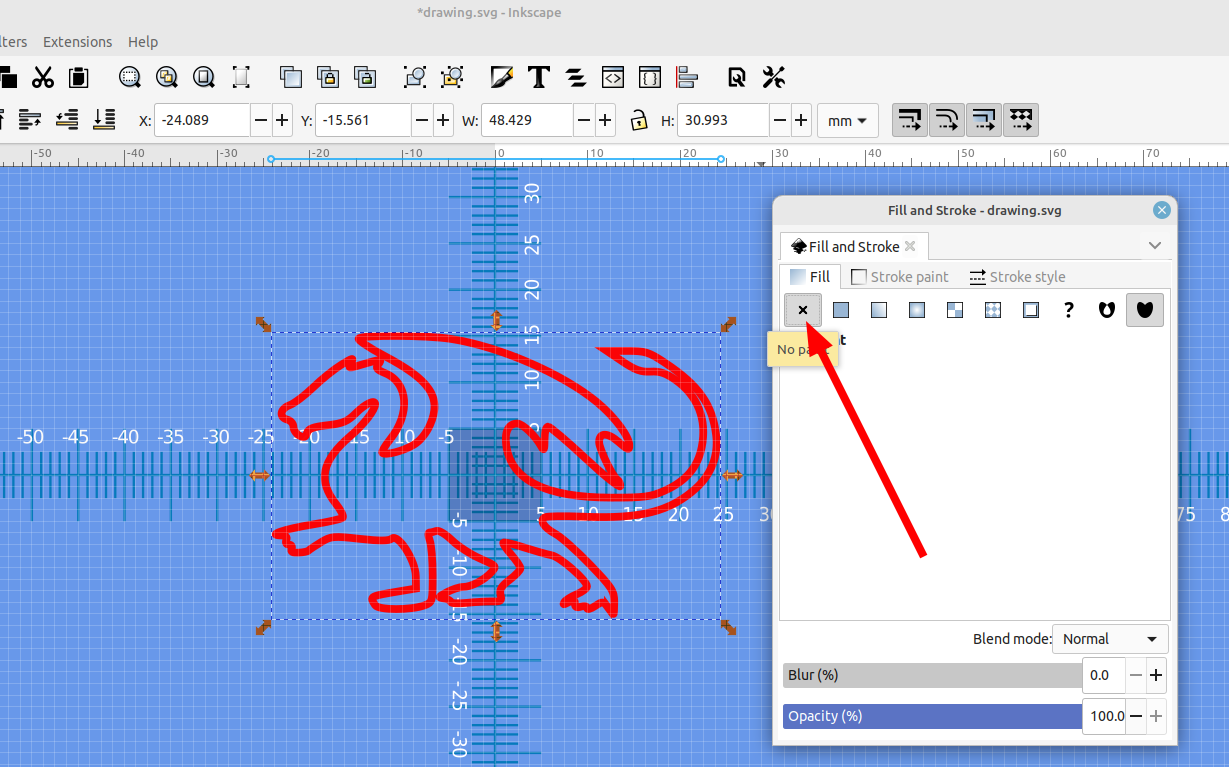

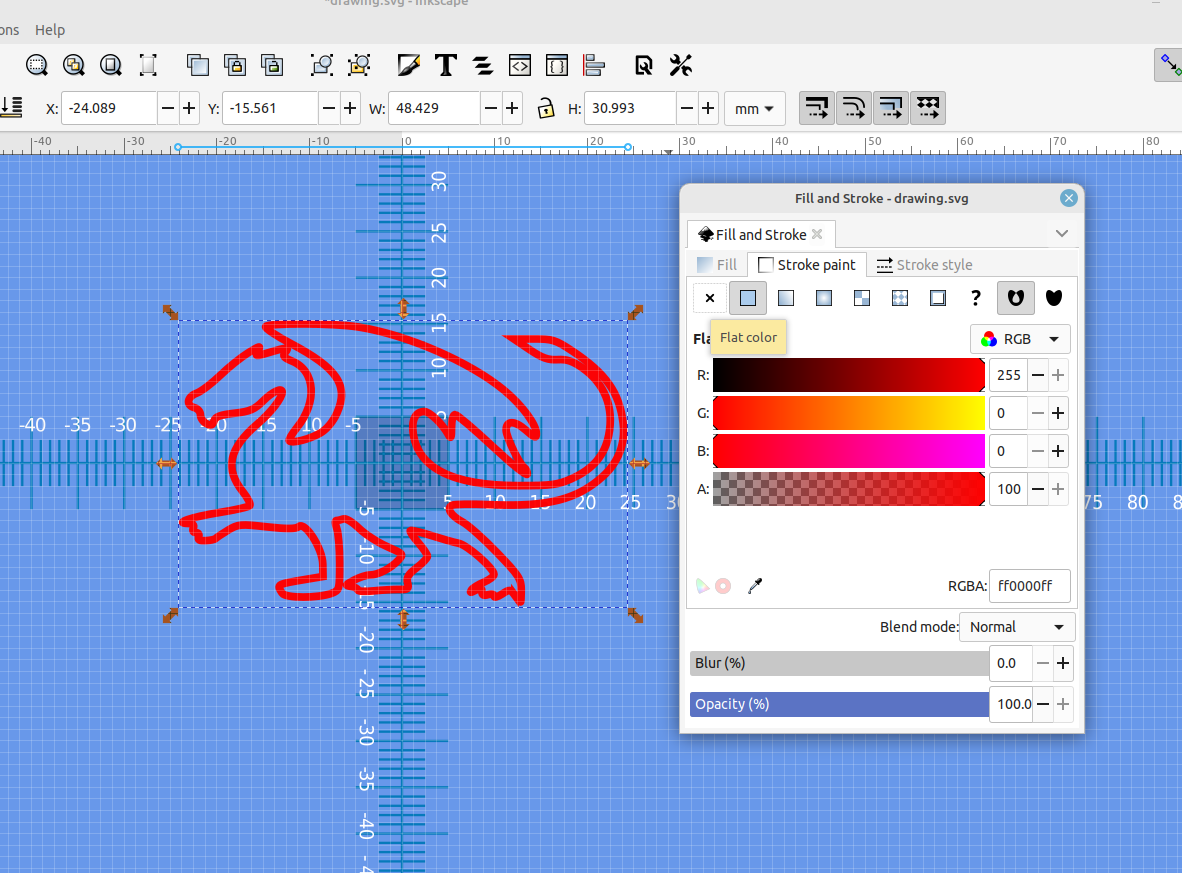

Next I opened the fill and stroke dialog and turned off the fill and turned on the stroke giving me an outline of the traced shape

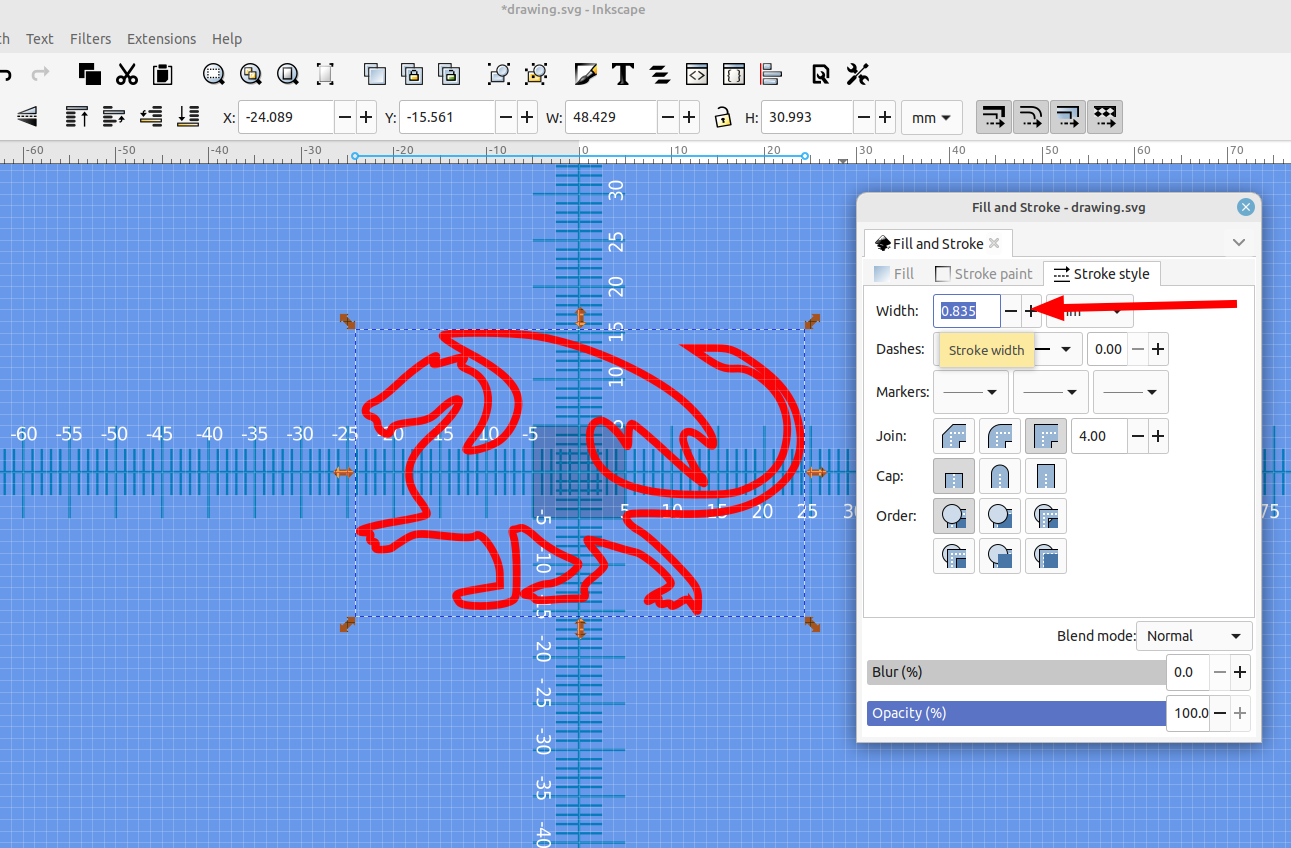

You can adjust the stroke width so the walls of the outline will be thick enough when you print it, probably at least twice the thickness of your nozzle size but not smaller than the nozzle size

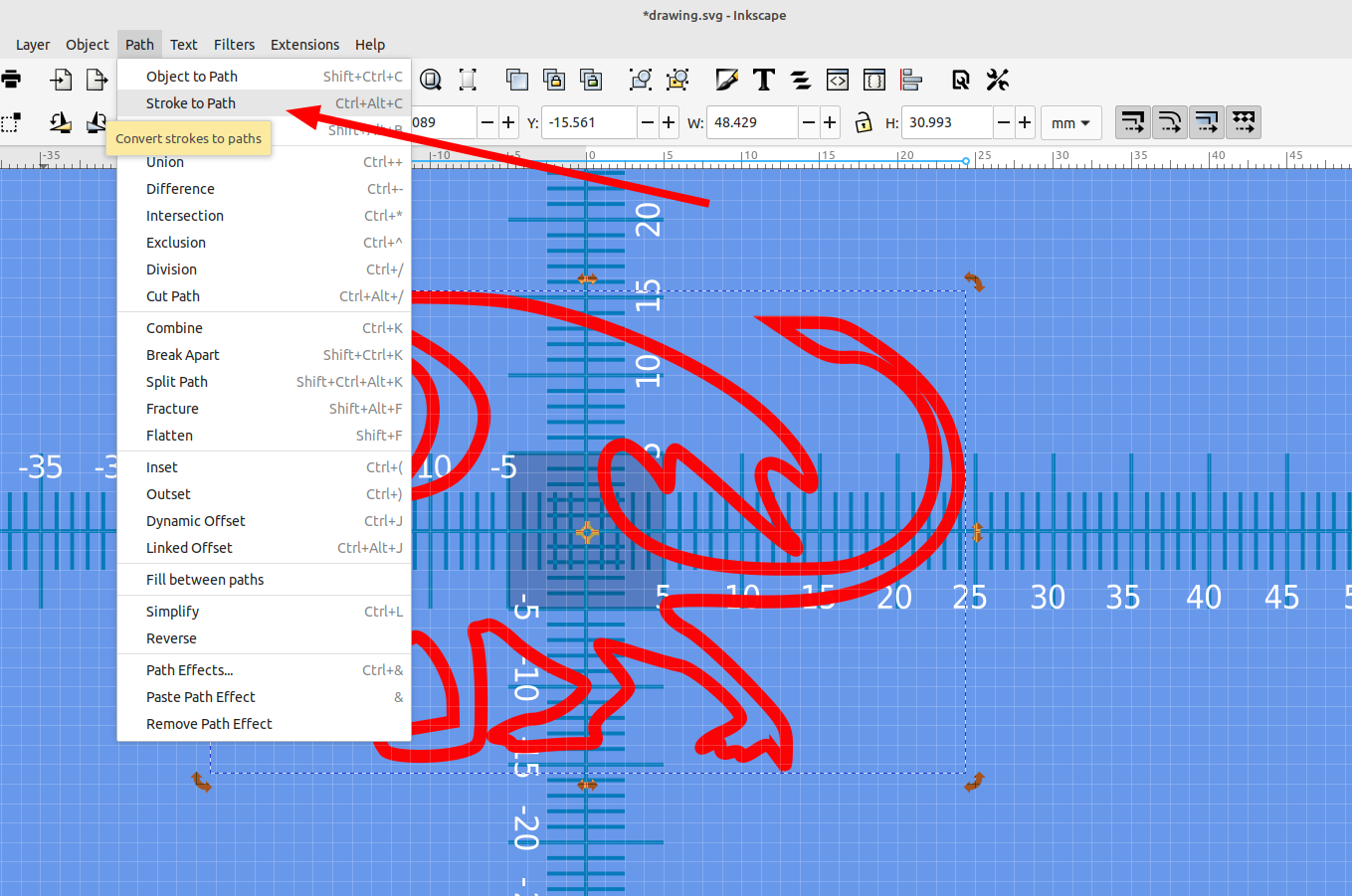

Then goto Path>Stroke to path to convert the outline to a path

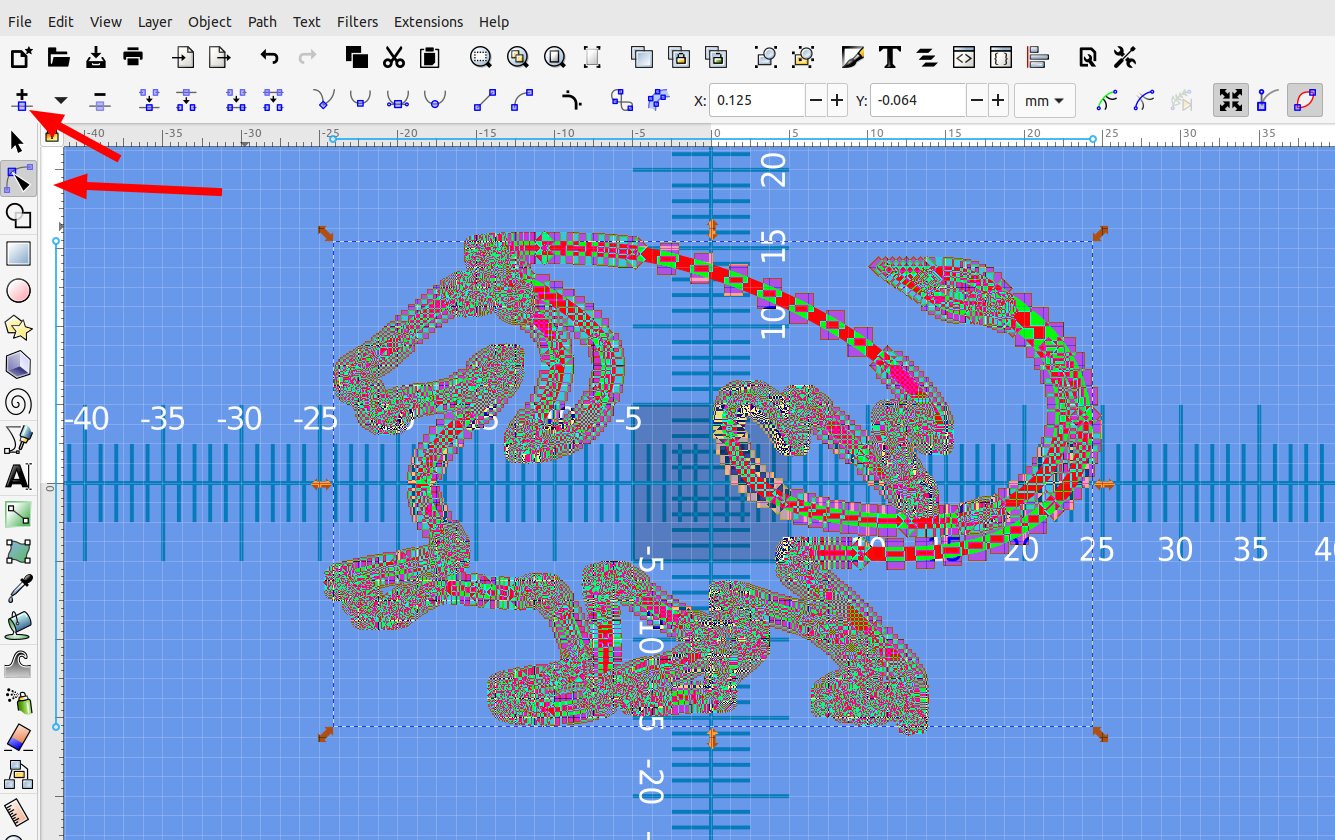

I added nodes to make the outline smoother, you probably only need to click add nodes 1 or 2 times because you don't really need a lot of detail.

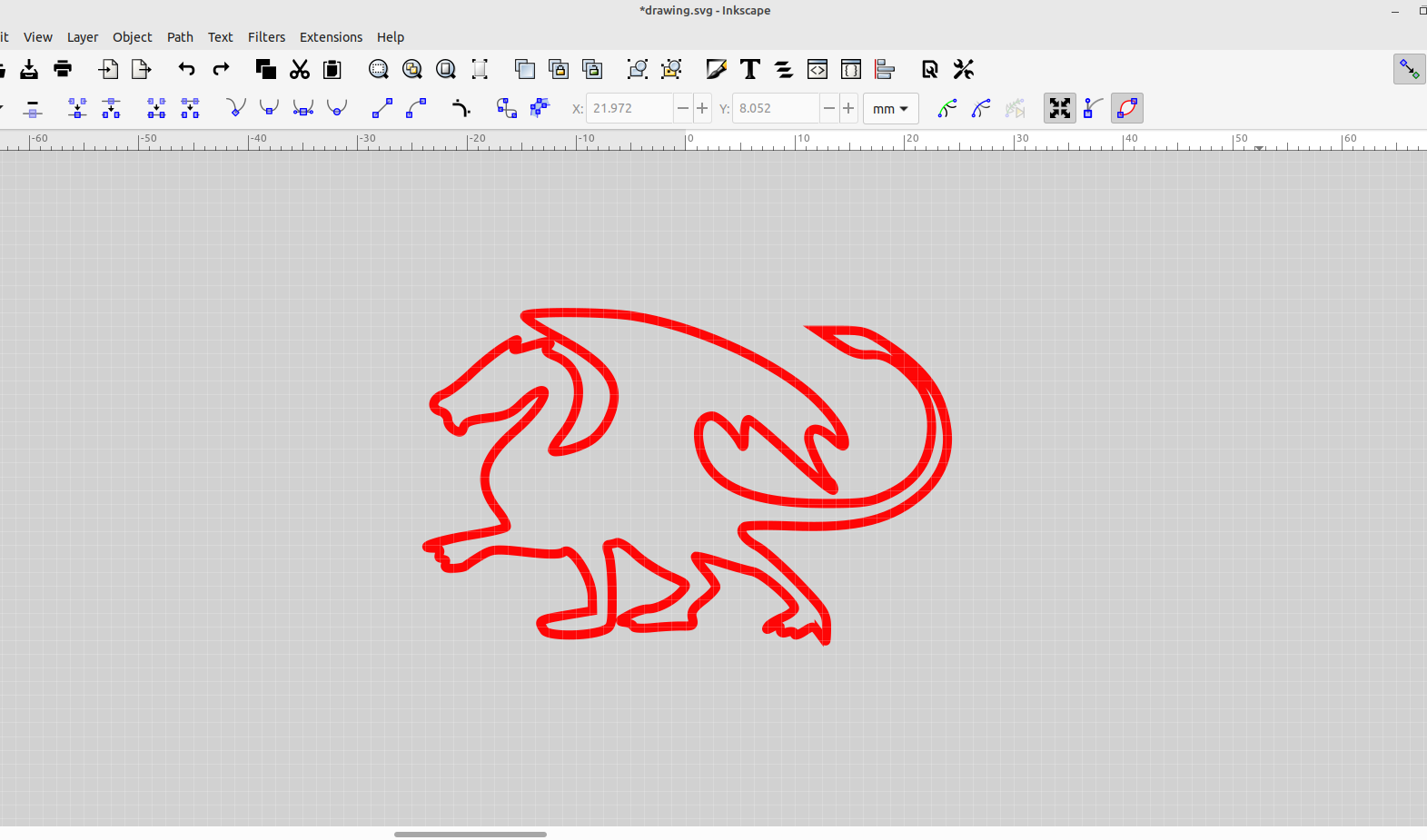

Next I made sure the outline was on layer 1, hid any other layers I didn't want and saved the files as an Inkscape .svg

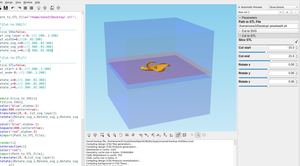

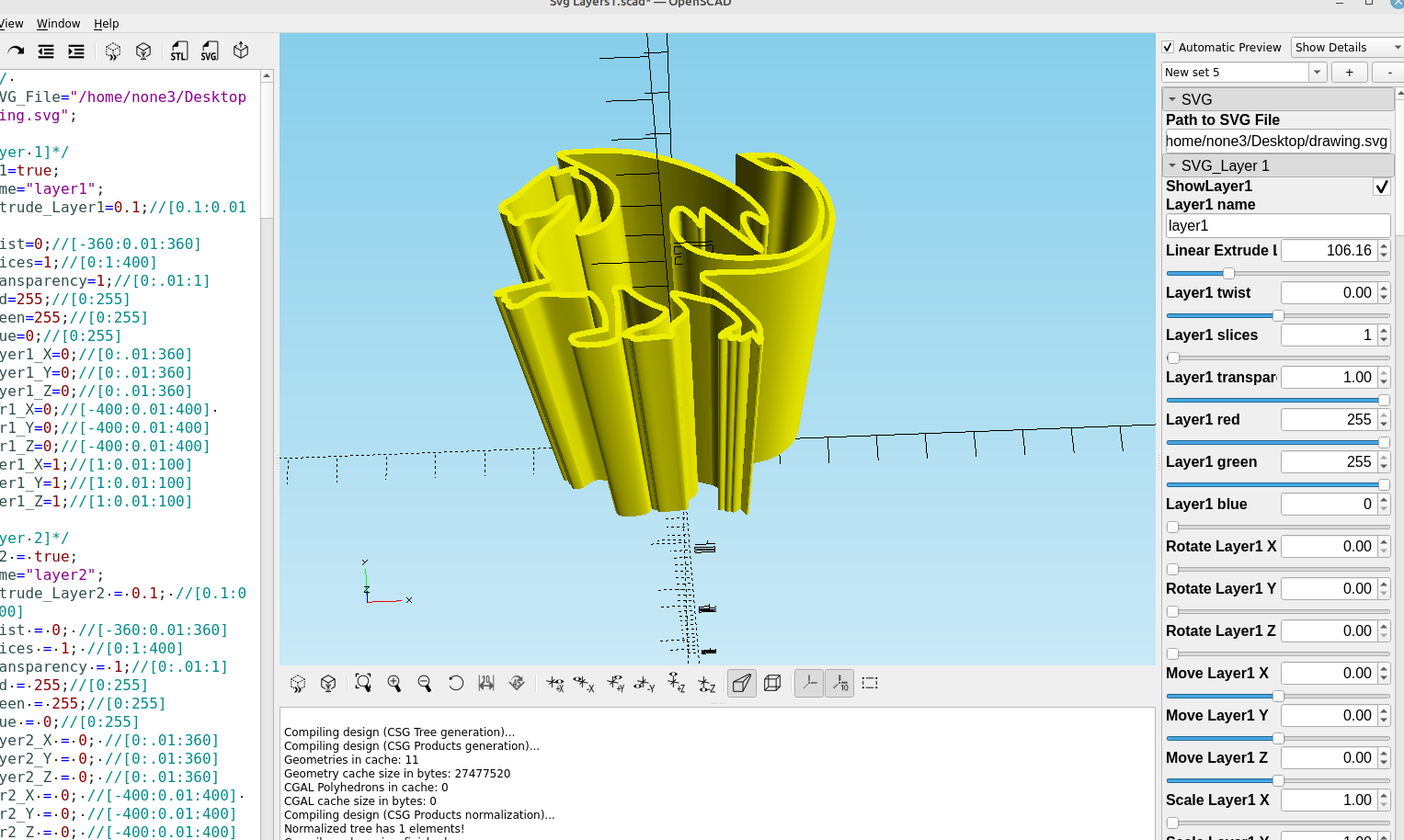

In post #68 I made a few modules for OpenScad so you could import SVG layers and extrude them. I opened it up, imported my outline and extruded it to the height I wanted

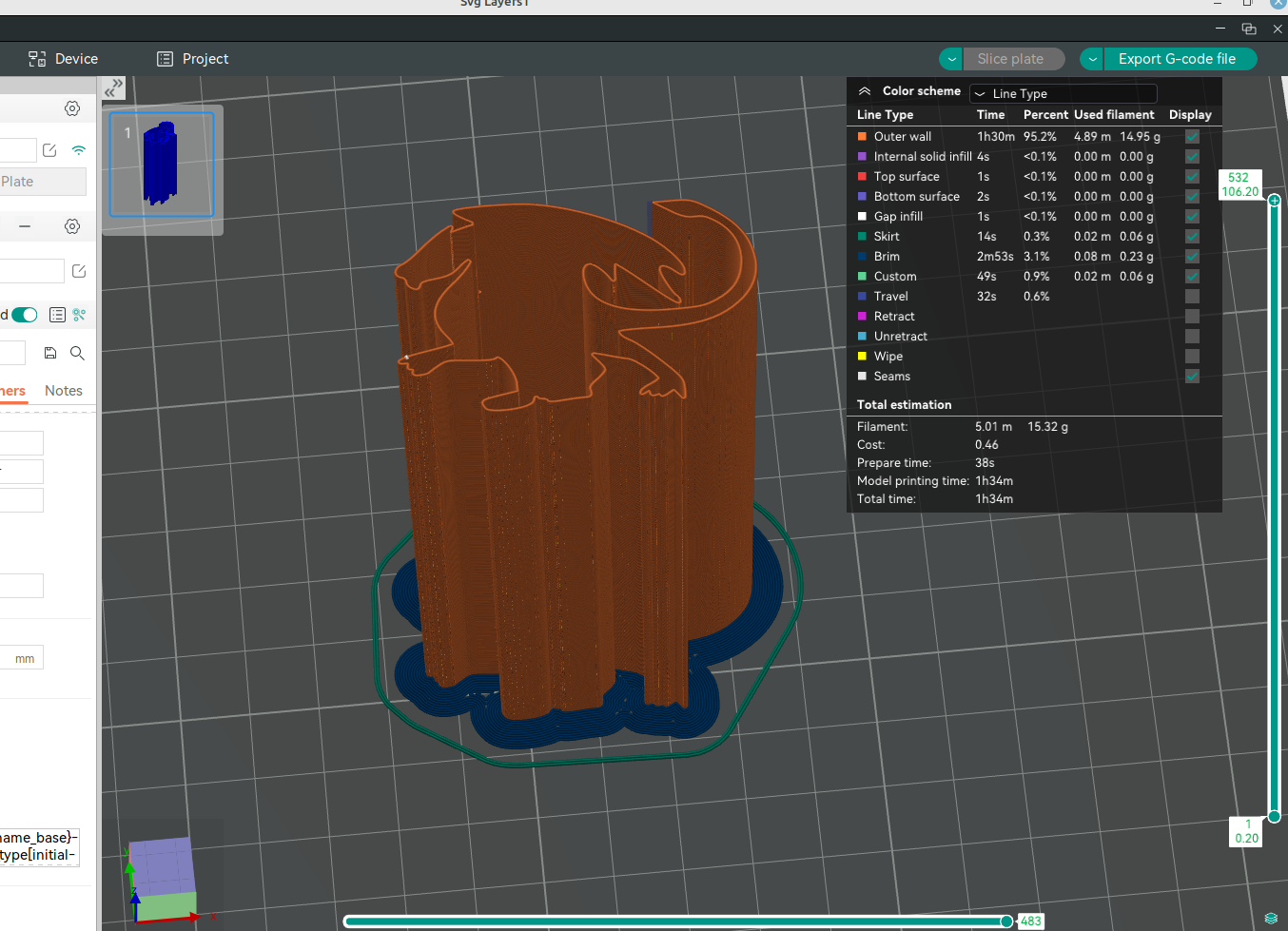

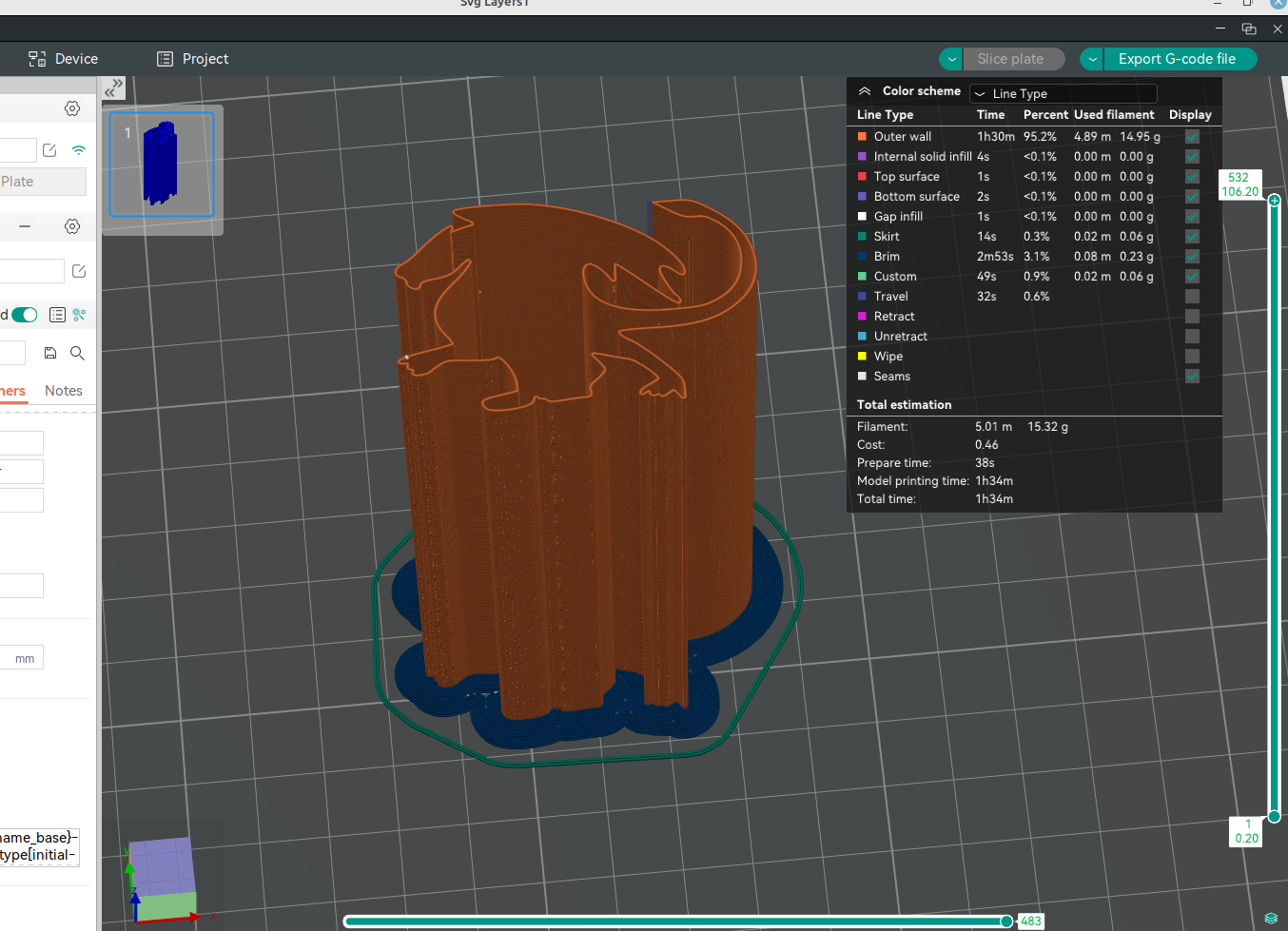

Next I loaded it into Orca slicer and sliced it, the procedure is pretty much the same for most slicers these days, vase mode will probably work fine and will save a bunch of print time, some experimentation with the wall thickness may need to be done depending on how well the pattern turns out after everything has been forged

Making a Damascus steel knife is probably out of the realm of possibility for most 3d printing enthusiasts due to the specialized equipment involved, but learning about the process may open the door to other interesting advancements in home manufacturing and this is another example of the cool things that can be made when two manufacturing processes combine.